|

Vipeak Heavy Industry Machinery Co. Ltd

|

Belt Conveyor/ continuous conveyor

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Belt conveyor (Belt conveyer) is the materiel transporting machine which transports the materiel in a certain line.

Belt Conveyor/ continuous conveyor:

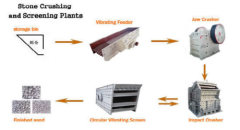

Raw Materials: River Gravel, Granite, Basalt, Quartz, Iron ore, Diabase, Limestone, Coal Gangue etc.

Application: Aggregate Field, Concrete Mixing Plant, Dry Mortar Plant Desulfurization, Quartz Sand etc.

Belt conveyor (Belt conveyer) is the materiel transporting machine which transports the materiel in a certain line. Conveyor belt also can be named continuous conveyor. The Belt conveyor can carry horizontal, oblique and vertical transporting and also can be composed into a space conveying line. This conveying line generally is fixed. The Belt conveyor's conveying ability is big and conveying distance is long. Belt conveyor also can complete several technological operations in the conveying process, so it is widely used in all kinds of industry.

Vipeak conveyors consist of standard parts, which are advanced and simple in structure, easy to maintain. They are widely used in mining, metallurgical and coal industry to transfer sandy or lump material, or packaged material. According to different transferring equipment, the transfer system can be one independently or multi-conveyors or combined with other transfer equipments. The Belt Conveyor can be installed horizontally or aslope to meet the needs of different transfer lines.

The Belt Conveyors can be operated in the circumstance temperature range from -20℃ to +40℃. The temperature of transferred material by this Belt Conveyor should be lower than 50℃.

Why choose vipeak: The Belt conveyor manufacture by vipeak has the advantage of large transfer quantity, simple structure, easy maintenance and standard parts.

Belt Conveyor application :

Jaw Crusher

Impact Crusher

Hammer Crusher

Symons Cone crusher

Belt Width (mm) | Belt Length (m)/Power (KW) | Belt Speed (m/s) | Capacity (t/h) | ||

400 | ≤12/1.5 | 12-20//2.2 | 20-25/3 | 0.8-2 | 40-80 |

500 | ≤12/3 | 12-20/4 | 20-30/5.5 | 0.8-2 | 78-191 |

650 | ≤12/4 | 12-20/5.5 | 20-30/7.5 | 0.8-2 | 131-323 |

800 | ≤10/4 | 10-15/5.5 | 15-25/7.5 | 1.0-2 | 278-546 |

1000 | ≤10/5.5 | 10-20/7.5 | 20-25/11 | 1.0-2 | 435-853 |

1200 | ≤10/7.5 | 12-20/11 | 20-25/15 | 1.0-2 | 655-1284 |

Note: actual power will be decided by the complete set. Max. angle when working of Belt Conveyor: | |||||

Material | β | Material | β | Material | β | Material | β |

Lump coal | 18° | 0-120mm ore | 18° | Wet concentrate | 20° | Salt | 20° |

raw coal | 20° | 0-60mm ore | 20° | Dry concentrate | 18° | Moulding sand | 24° |

Coal powder after washing ① | 21° | 40-80mm bituminous shale | 18° | Limestone after screening | 12° | Waste sand | 20° |

Hard coke after screening | 17° | 20-40mm bituminous shale | 20° | dry sand | 15° | Stone with screening | 18° |

0-25mm hard coke | 18° | 0-200mm bituminous shale | 22° | Sand mixed with gravel | 18-20° | cement | 20° |

0-3mm hard coke | 20° | Dry and loose earth | 20° | Quarry sand | 20° | Blocky dry clay | 15-18° |

0-350mm ores② | 16° | Wet earth | 20-23° | Wet sand | 23° | Powder dry clay | 22° |

Note:①Including clean coal, middlings coal and waste coal. ②Including ferrous metal, non-ferrous metal, rock, limestone and so on. | |||||||

.jpg)